Reindustrialize with Modern Metal Mills

I've been in the trenches with American metal mills, and let me tell you, the lead times are a killer. Eight weeks for an aluminum plate? Eight months for stainless steel? It's clear we need to rethink and reindustrialize. Here's how we're tackling these challenges head-on. With international competition breathing down our necks and lead times that just don't cut it anymore, it's crucial to support our modern manufacturers. I'm laying out practical steps and solutions to slash these delays. We can't afford to wait eight months for stainless steel needed in aerospace and defense. I got burned several times before realizing we need to operate differently for real impact.

Eight weeks for an aluminum plate, that's what I've seen in American metal mills. Eight months for stainless steel needed in aerospace and defense? Unthinkable! If you're in the same boat, you know something's gotta give. I've worked with modern manufacturers and know reindustrializing is our ace in the hole. With international competition pressing us, our current lead times just don't cut it. I'm going to show you how we can slash these delays and support our industries. It's time to act, and I'm bringing you concrete solutions I've tested in the field to get us back on track. We need to stop getting left behind and regain the edge.

Understanding the Challenges in American Metal Mills

Let's dive right into the heart of the problem: lead times. When you need an aluminum plate, you're looking at waiting around 8 weeks. And stainless steel? Try 8 months. These delays aren't just frustrating; they create real bottlenecks. Meanwhile, international competitors are swooping in with faster and often cheaper alternatives. The need for modernization in our processes and technology is more urgent than ever. These inefficiencies directly affect our ability to support crucial sectors like domestic aerospace and defense.

As a practitioner, I see these challenges daily. Without modernization, our mills risk losing relevance against more agile and better-equipped international players. Reindustrialization is not just an option; it's an absolute necessity.

International Competition: What We're Up Against

Global mills, especially in Europe, Africa, and Asia, aren't just competing on price. They have more advanced manufacturing processes that allow them to deliver faster. It's a scenario where sometimes, it's worth paying a bit more for speed. Understanding what they do differently is crucial for formulating our strategies. Technologies used abroad, like automation and AI, are levers we need to adopt to stay competitive.

- International mills benefit from more advanced technology.

- Speed of delivery is as important as price competitiveness.

- Understanding what others do differently is essential.

- Evaluate trade-offs between cost and lead time.

Reindustrialization: The Path Forward

Investing in technology and infrastructure is crucial for reindustrializing the U.S. This requires collaboration between the government and the private sector. Successful reindustrialization examples show it's possible, but it requires sustained commitment. Finding a balance between modern manufacturing needs and traditional methods that have proven themselves is key. I've orchestrated projects where modernization led to significant cost reductions and efficiency gains. But watch out, don't fall into the trap of modernizing for modernization's sake; each investment needs to be carefully evaluated for its concrete business impact.

Companies that successfully transition often do so with a clear strategy and solid partners. For those looking to understand how to reindustrialize successfully, I recommend learning from proven best practices.

Supporting Modern Manufacturers like RMFG and Forge Automation

Modern manufacturers, such as RMFG and Forge Automation, are at the forefront of current challenges. They've embraced automation to reduce lead times and costs. For instance, by integrating automated systems, I've been able to significantly reduce production downtimes, which directly impacts delivery times. These companies show that innovation, though costly at first, can offer substantial return on investment.

The lessons learned from these experiences show that while the initial investment is high, the long-term benefits more than justify the costs. This is where manufacturers need to focus to remain globally competitive.

Call to Action: Industry Solutions via YC

YC plays a crucial role in fostering innovation in the metal industry. For startups, this is a golden opportunity to tackle these industrial challenges with innovative solutions. Collaboration is key to driving reindustrialization efforts. For those who truly want to make a difference, getting involved in these initiatives can be a great starting point. As a builder who's been involved in such initiatives, I can say the impact is not only tangible but also rewarding.

- Opportunities for startups to solve industrial challenges.

- Collaboration is essential to drive reindustrialization.

- Practical steps to get involved and make a difference.

For those looking to learn more about how to get involved, I recommend visiting YC's resources and looking at past success stories.

Reindustrializing our American metal mills is more than just a necessity; it's a golden opportunity. First, we need to really grasp the challenges posed by our current lead times: eight weeks for an aluminum plate, eight months for stainless steel critical to aerospace and defense. That's a bottleneck I can't ignore. Then, I look to international competitors who are leading the way with modern innovations. But watch out, it doesn't mean blindly copying; we need to adapt to our needs and realities. Finally, I support our modern manufacturers who are already doing wonders with limited resources. Looking forward, modernizing our mills could be the boost our industry needs to regain competitiveness. So, join the movement, whether you're a manufacturer, investor, or innovator. Let's take the reins of this transformation. To dive deeper, I recommend watching the original video "Reindustrialize With Modern Metal Mills" on YouTube. It digs into these issues with practical insights.

Frequently Asked Questions

Thibault Le Balier

Co-fondateur & CTO

Coming from the tech startup ecosystem, Thibault has developed expertise in AI solution architecture that he now puts at the service of large companies (Atos, BNP Paribas, beta.gouv). He works on two axes: mastering AI deployments (local LLMs, MCP security) and optimizing inference costs (offloading, compression, token management).

Related Articles

Discover more articles on similar topics

Building Reusable Rockets: Challenges and Wins

When I first thought about building reusable rockets, I was starting from zero. No roadmap, no precedent—just a belief that it could change the game. Back then, nobody was tackling it, the industry wasn't even trying. But I knew it was something worth pushing for. So we took that crazy idea and turned it into reality. Of course, it wasn't without challenges. Starting a space company isn't child's play, especially when you're one of the first to believe that reusing rockets is possible. I'll walk you through how we tackled these obstacles, from the initial conviction to the crucial entrepreneurial decisions. It's a story of perseverance, innovation, and believing in ideas that, on paper, seemed impossible.

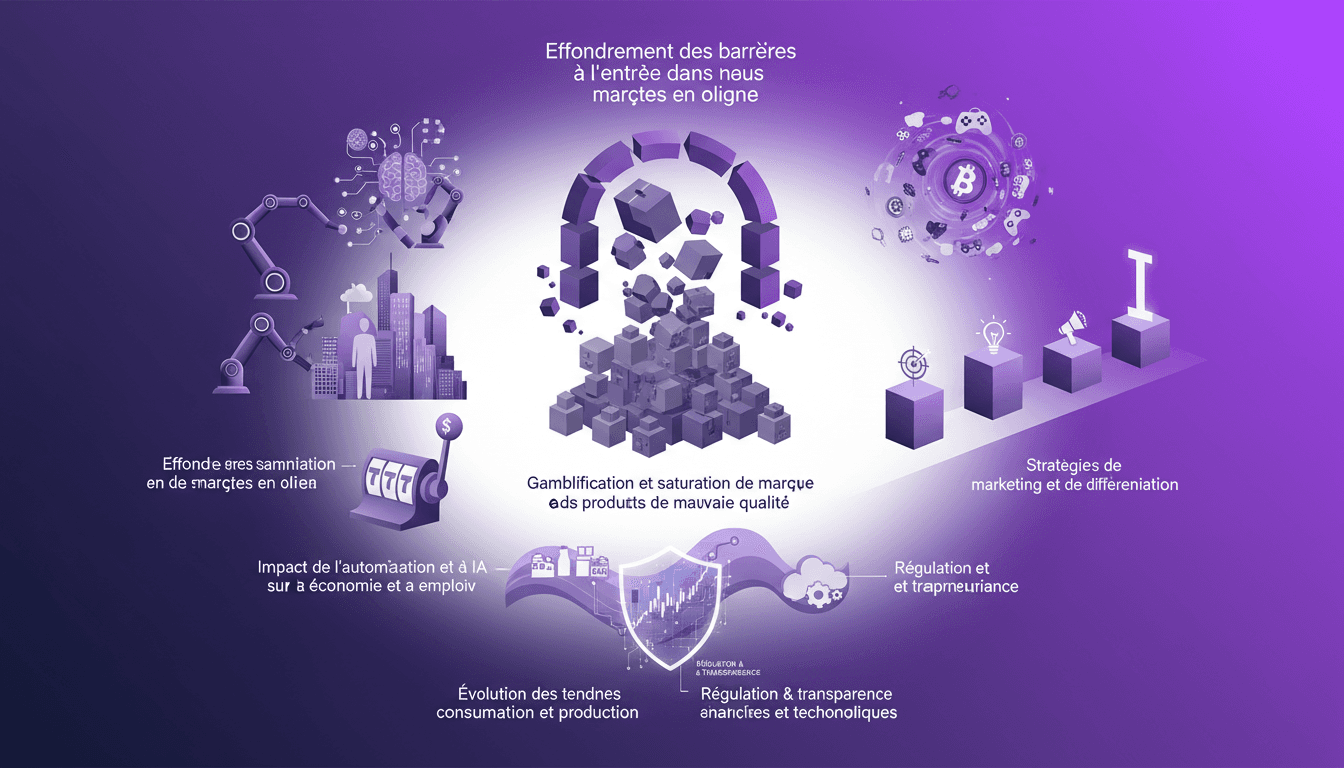

Succeeding in 2026: Strategies for the Digital Age

I've watched the digital landscape shift dramatically. And trust me, if you don't adapt, you'll be left behind. It all started with the collapse of entry barriers in online markets, unleashing a flood of products—sometimes not the best—onto the scene. With gamblification and automation seeping into every corner, succeeding in 2026 requires sharp strategy. I tackle this by orchestrating solutions that blend marketing innovation and smart AI use. But watch out—regulation and transparency are becoming crucial to avoid pitfalls. In this sea of change, anticipating consumption and production trends (crypto and gaming are booming) is key.

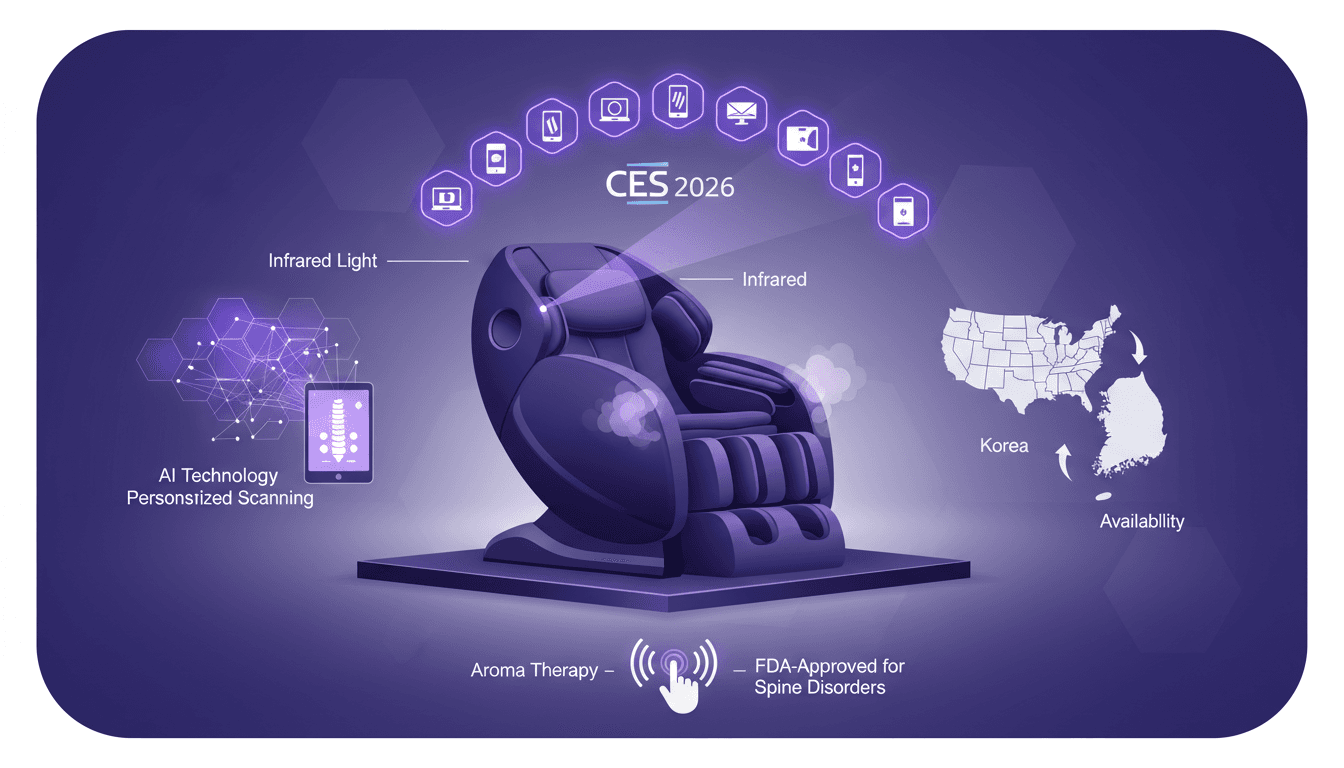

In-Home Spa Treatment: CES 2026 Innovations

I was at CES 2026, and let me tell you, the in-home spa tech blew my mind. Imagine a massage chair that's FDA-approved for spine disorders. I tried it, and here's how it works. CES introduced 12 cutting-edge products, but this chair stole the show. With personalized scanning, infrared light therapy, and aromatherapy, it redefines home wellness. Available in Korea and the United States, it offers an unparalleled relaxation experience. Let's dive into its features and see what makes it stand out.

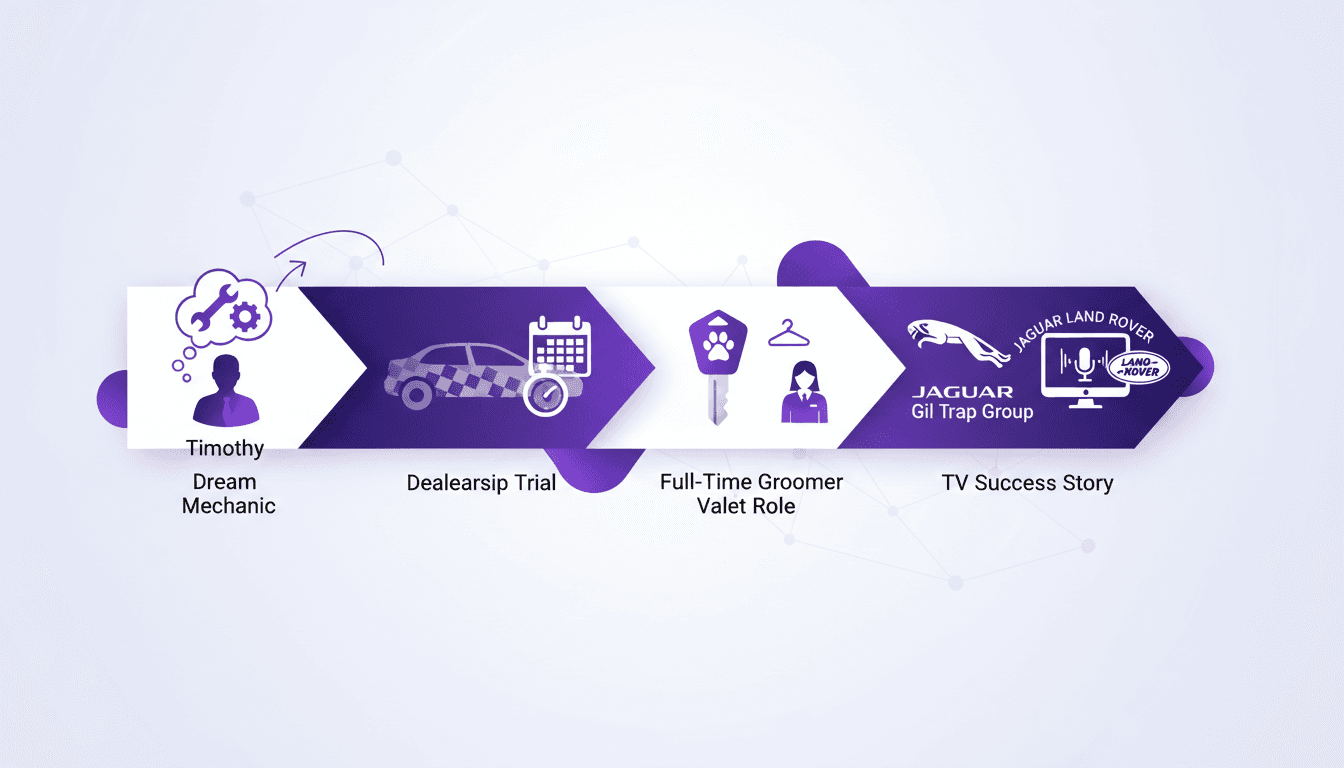

Becoming a Mechanic: Timothy's Dream

I remember the first time I set foot in a dealership, driven by the dream of becoming a mechanic. For Timothy, the engine was the same. It's not just about fixing cars; it's the journey from dream to reality. Timothy seized the opportunity with Jaguar Land Rover Gil Trap Group, starting with a week-long experience that changed everything. It often takes a plan, a trial, and sometimes a bit of luck. With a full-time offer as a groomer valet, Timothy watched his dream unfold live on TV. A great lesson on turning passion into a career!

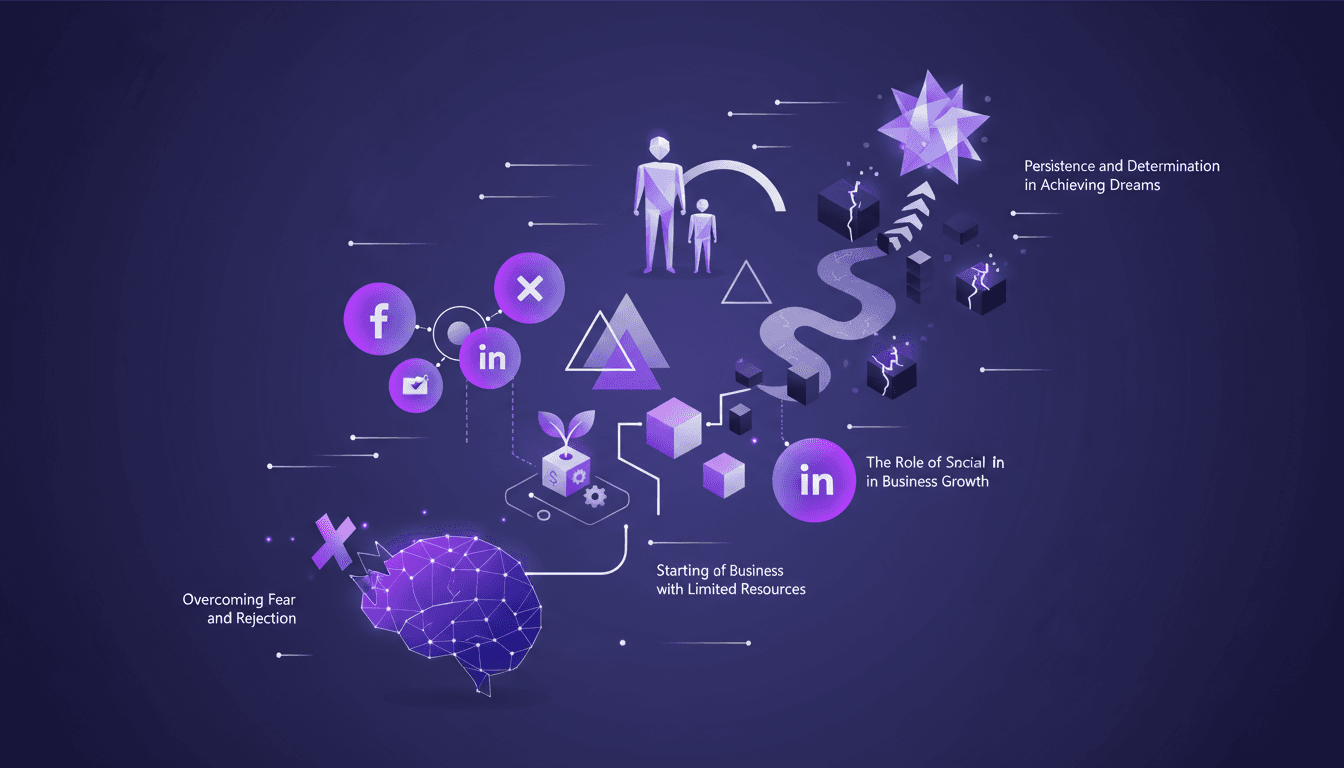

Overcoming Fear: Start Your Business

I dared myself to step out of my comfort zone and start a business with barely any resources. This is the story of Joe, a shy guy who faced his fears to start his business journey. Through the power of social media, mentorship, and sheer determination, he turned every challenge into a growth opportunity. I documented his journey like a motivational documentary, highlighting the impact of support and persistence on entrepreneurship. You'll see how, with just an hour to convince three strangers for a haircut and only 0.01% of the business bought for £1,000, Joe overcame each hurdle. Don't let limited resources intimidate you, because true strength lies in determination and constant learning.